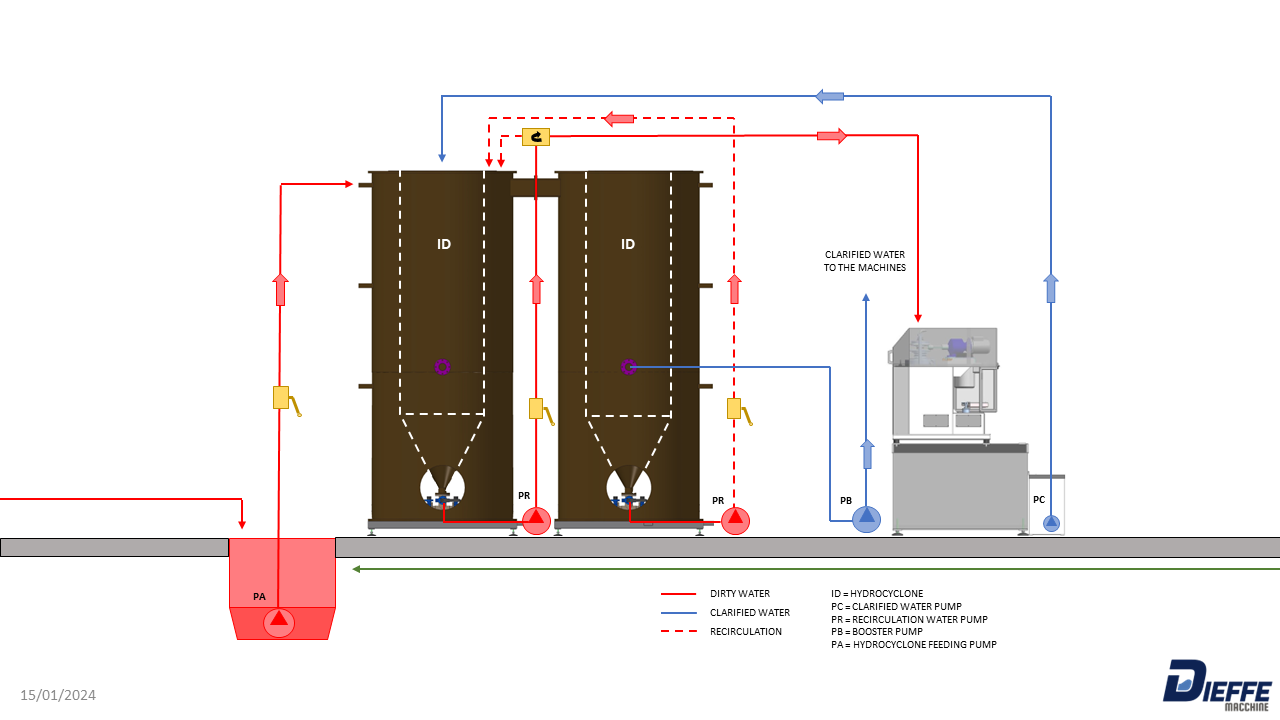

Planned installation for a total flow rate (max) of 2,200 l/min

The dirty water arriving at the sump is sent by submersible pump to the hydrocyclone. Due to the effect of gravity and the thrust given by the tangential injection system, the liquid descending in a spiral along the inner walls of the hydrocyclone separates the part with greater content of glass powder from the water, which, due to the gravitational effect, rises inside the central cylinder; the powder separated from the water is deposited in the cone of the hydrocyclone from where it is sent via a pump into the rotor of the centrifuge. The particles in suspension, contained in the liquid, by virtue of the increased weight will be pushed, thanks to the force "g", against the wall of the basket placed in rotation, compressing and causing the clarified liquid to flow out, which, collected in the tank, located behind the centrifuge, will be relaunched in the hydrocyclone. From the hydrocyclone the liquid, clarified, will be sent by pump to the machines.

The water coming out of the centrifuge and re-launched in the hydrocyclone is clarified at 5 μ m (5 microns). This means that solids of silica, diamonds and polishing compounds, glass, above 5μm will be separated. The removal of the sludge produced by the centrifuge is done automatically with cycles set by PLC.