Centrifuge with independent fully automatic solid discharge

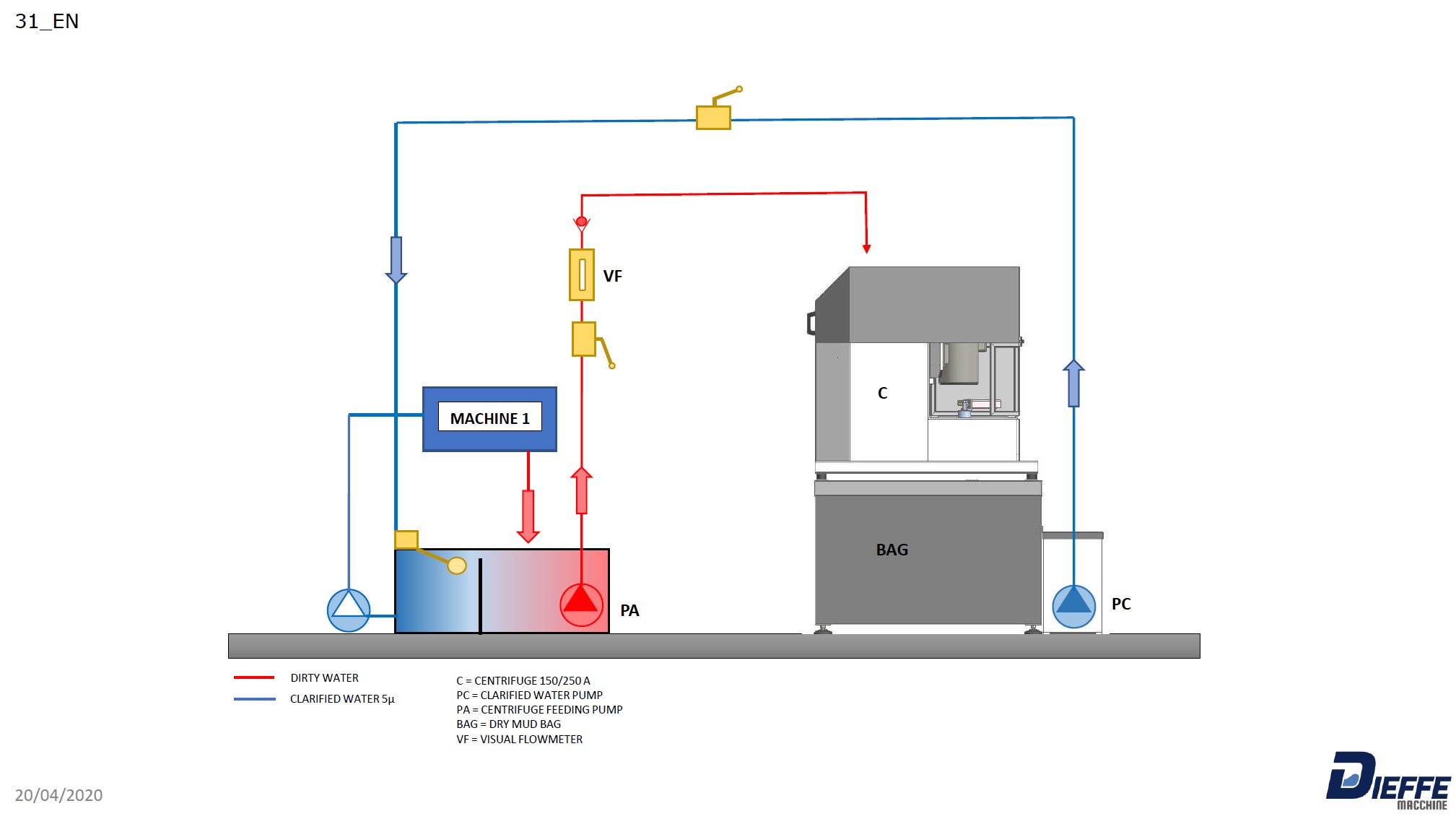

This mechanical centrifuge treatment system is for the removal of solids from water used in processing glass, stone and ceramic materials. Waste and solids which are suspended in the water, are separated out by a centrifugal action, with the clean water suitable to be recycled and reused for the same process. Clarification takes place by pumping the dirty water to the removable centrifuge drum at a controlled flow rate, directing it strategically into a specially shaped and purposely designed rotating drum cylinder. The unique design of the drum makes the water flow and rotate, and naturally rise. Two actions happen during this process: solids are forced to the outside because of their weight compared with water (g-force), and clean water is channelled to the top and centre for recycling. Water is clarified to 5μm. This means that production waste ground materials: silica, diamond and polishing compounds glass, greater than 5μm, will be separated out. The clarified water is sent back to the machine for re-use.

The removal of sludge collected by the centrifuge is done automatically. At scheduled times, which is programmed by using a keypad on the PLC, the centrifuge will stop to get rid of the sludge. At the end of this auto-cleaning phase, the centrifuge will restart a new work cycle. A tempi programmati tramite tastierino sul PLC, la centrifuga effettuerà un arresto per evacuare i fanghi accumulati. Al termine dell’operazione la centrifuga ricomincerà un nuovo ciclo di lavoro.

The centrifuge can also be equipped with a remote start and stop function.