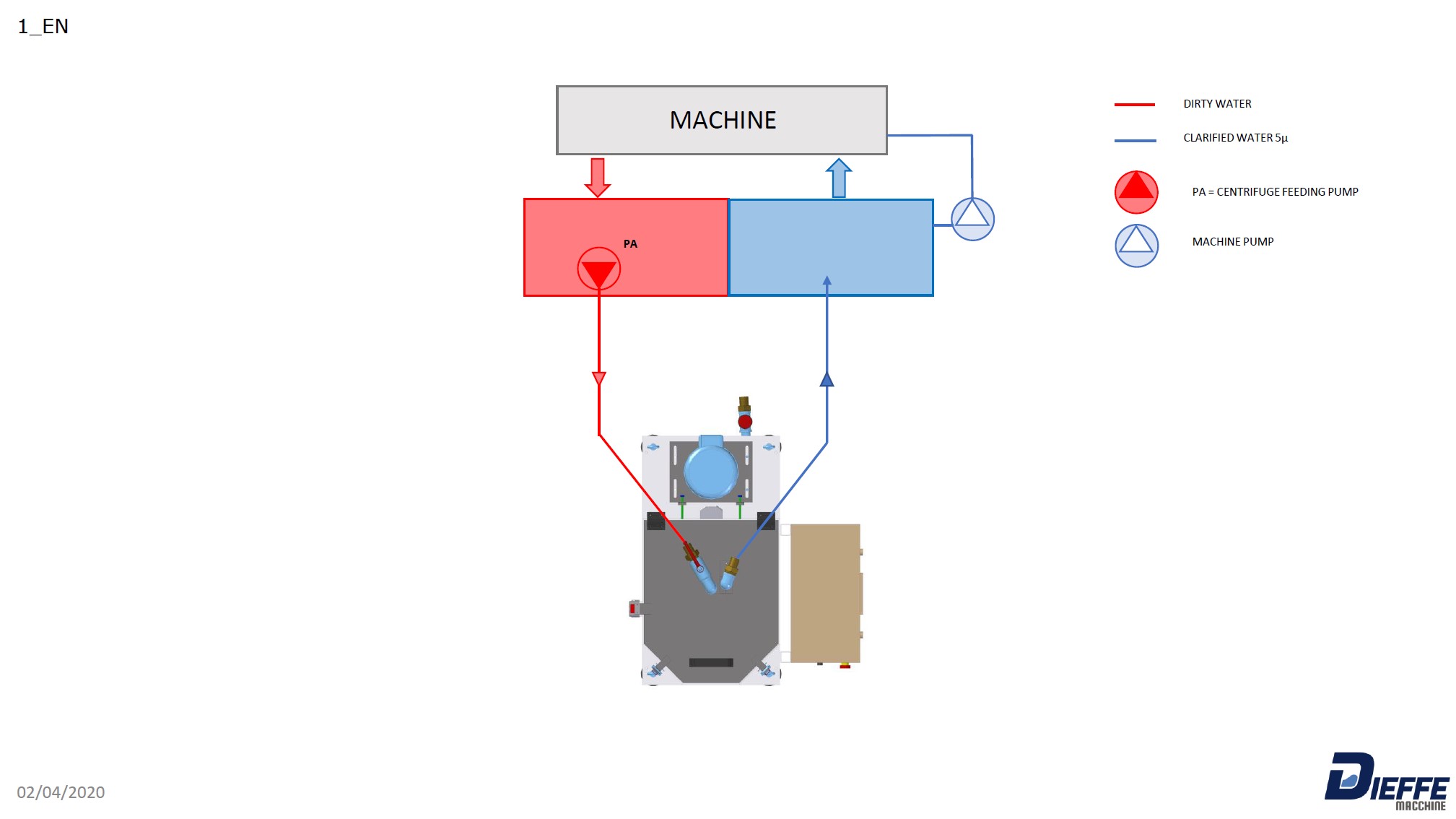

Manual centrifuge for a single machine

Our centrifuge is powered by a submerged pump located in the tank of the process machine. This mechanical centrifuge treatment system is for the removal of solids from water used in processing glass, stone and ceramic materials. Waste and solids which are suspended in the water, are separated out by a centrifugal action, with the clean water suitable to be recycled and reused for the same process.

Clarification takes place by pumping the dirty water to the removable centrifuge drum at a controlled flow rate, directing it strategically into a specially shaped and purposely designed rotating drum cylinder. The unique design of the drum makes the water flow and rotate, and naturally rise. Two actions happen during this process: solids are forced to the outside because of their weight compared with water (g-force), and clean water is channelled to the top and centre for recycling. Water is clarified to 5μm (5 microns). This means that production waste ground materials: silica, diamond and polishing compounds glass, greater than 5μm, will be separated out. The clarified water is sent back to the machine for re-use

The sludge waste produced by the centrifuge is manually discharged by removing the drum and cleaning by hand. It can also be rested upside down over a collection bag for it to fall out by gravity, once dry. The drum is manufactured from special thermoplastic non stick material which allows easy emptying of waste contents.

The DFL 100 M with wheels has the same features as the DFL 100 M, making it more agile in movement for those with more dynamic needs